Best practices are part of our organizational culture

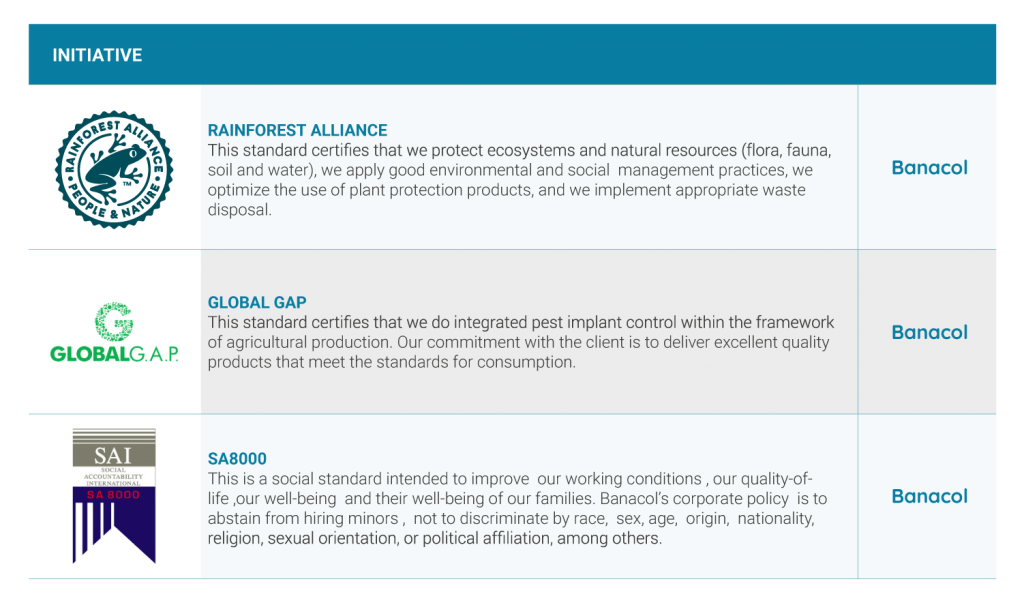

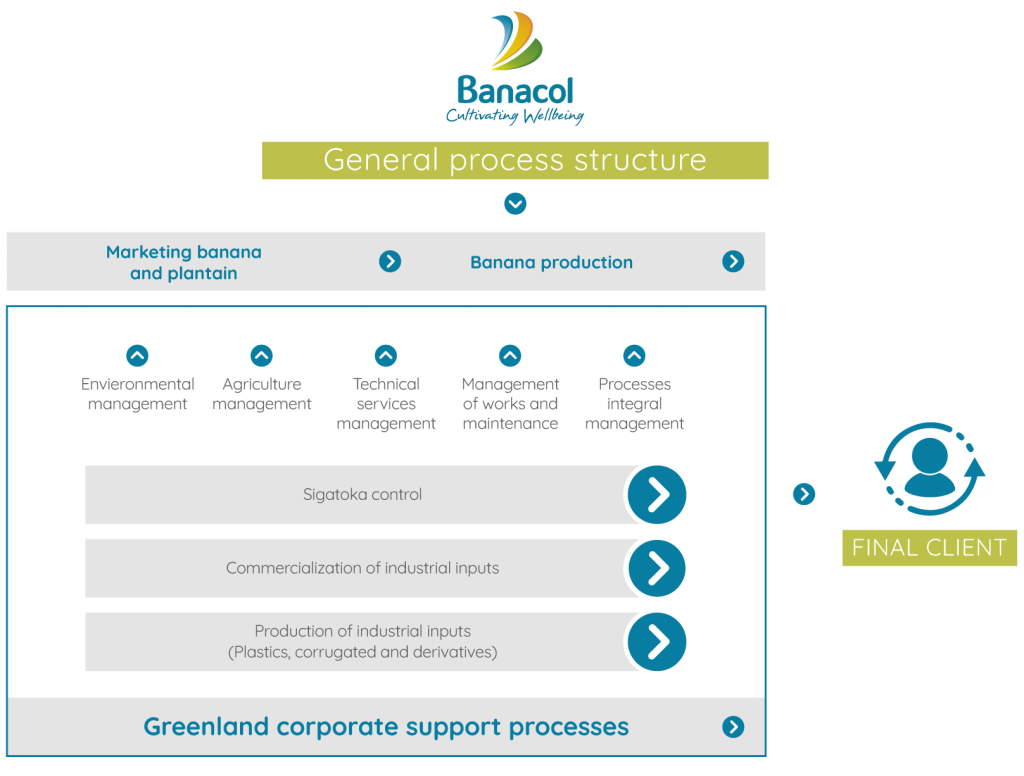

We define our processes and use domestic and international best practices as a benchmark that help us to adjust our actions to what the market requires and so meet our objectives.

We have teams in production, agriculture, integrated process management, quality, technical services, and corporate responsibility that are in charge of weekly monitoring, evaluating, and measuring the tasks in our plantations so we can have high quality products that meet the environmental requirements accepted by best agricultural practices and backed by international certifications that help us meet the requirements of the market, receive permanent feedback, meet our productivity and returns goals, all with the support of high-technology.

(102-12)